Understanding International Supply Chain Management

Think of international supply chain management as conducting a global orchestra. Each musician—a supplier in Asia, a logistics partner in Europe, a customs agent in Durban—speaks a different language and plays a unique instrument. Your job as the conductor is to ensure they all play in perfect harmony to create a beautiful piece of music: a product delivered on time and on budget to a happy customer.

For South African exporters, this means orchestrating everything from sourcing raw materials in Gauteng to delivering finished products to a retail shelf in Berlin. It’s a fundamentally different discipline from its domestic counterpart. Managing a supply chain within South Africa has its complexities, but crossing borders introduces a new dimension of challenges.

The extended timelines, multiple currencies, and diverse regulatory environments create a far more intricate network. A delay of a few hours on a domestic route is an inconvenience; a similar delay at a major international port can cascade into weeks of disruption, costing thousands.

From Local Routes to Global Networks

Successful international supply chain management transforms these potentially chaotic global networks into coordinated operations that deliver value at every touchpoint. This requires a shift in thinking. For example, a South African agricultural cooperative exporting fresh fruit must manage not just the journey from farm to port, but also the intricate cold chain logistics across oceans, compliance with foreign food safety standards, and fluctuations in currency exchange rates that can impact profitability.

This diagram illustrates the basic flow, which becomes exponentially more complex when international borders are crossed.

The image shows a simplified model, but it highlights the distinct stages—from sourcing raw materials to final delivery—that must be coordinated. When operating internationally, each arrow represents a potential point of failure: a customs hold-up, a lost container, or a documentation error. This is why timing and visibility become exponentially more critical when your operations span continents.

To put this into perspective, let's compare the two environments side-by-side. The following table breaks down the key differences between managing a supply chain at home versus abroad.

Domestic vs International Supply Chain Complexity

A comparison showing the key differences between managing domestic and international supply chains

| Aspect | Domestic Supply Chain | International Supply Chain | Key Challenges |

|---|---|---|---|

| Logistics | Single mode of transport (e.g., truck) | Multiple modes of transport (sea, air, rail, road) | Coordinating handovers between carriers, managing different documentation for each mode. |

| Documentation | Simple invoice, waybill | Commercial invoice, bill of lading, certificate of origin, import/export declarations | Errors in documentation are a primary cause of customs delays and fines. |

| Lead Times | Short and predictable (hours or days) | Long and variable (weeks or months) | Increased inventory carrying costs, higher risk of stockouts or overstocking. |

| Regulations | One set of national/provincial laws | Multiple sets of national laws, trade agreements, and customs rules | Navigating different product standards, tariffs, and compliance requirements. |

| Payment & Currency | Single currency (ZAR), simple payment terms | Multiple currencies, complex payment methods (e.g., Letters of Credit) | Currency fluctuation risk, higher transaction fees, risk of payment default. |

| Communication | Single language, same time zone | Multiple languages, different time zones, cultural nuances | Misunderstandings can lead to costly mistakes in orders or shipments. |

This comparison makes it clear that going global isn't just about longer distances; it's about managing a completely different level of complexity across every function of your supply chain.

The South African Advantage

However, this complexity also presents a unique opportunity. South African businesses are strategically positioned at the crossroads of major shipping lanes connecting the East and West. By mastering international supply chain management, local exporters can turn this geographic advantage into a powerful competitive edge.

Instead of being a victim of global logistics, they can become masters of it, offering reliability and efficiency that rivals competitors anywhere in the world. The key is to move beyond simply shipping a product and begin architecting a truly global delivery system.

Building Your Supply Chain Foundation

Just as a skyscraper needs solid foundations to withstand powerful winds, a successful international supply chain rests on core pillars that provide stability in a volatile global market. For South African exporters, constructing this foundation is not just good practice; it is essential for survival and growth. Building a resilient operation means moving beyond simply reacting to problems and instead architecting a system that anticipates challenges and adapts seamlessly. This foundation is built on four critical pillars: visibility, flexibility, collaboration, and technology integration.

Think of visibility as your supply chain's nervous system. It’s the ability to see exactly where your shipment of Western Cape wine is at any given moment, whether it's leaving the Port of Cape Town or clearing customs in Rotterdam. Without this real-time insight, you are operating in the dark. This is where modern tracking systems and integrated platforms become indispensable, transforming ambiguity into actionable data.

Weaving Technology into the Fabric of Your Operations

Technology is the thread that weaves these pillars together. The global supply chain management market, valued at $21.95 billion in 2023, is rapidly expanding, with a strong focus on digitisation. South African businesses are increasingly adopting AI and automation to reduce errors and inefficiencies. This mirrors global trends where AI is expected to cut prediction errors by 20–50%. This move from manual processes to intelligent systems is what separates market leaders from the rest. You can find more about these trends in recent supply chain statistics.

This diagram shows how technology underpins key performance metrics in a modern supply chain.

The image illustrates how a digital control tower provides end-to-end visibility, which directly improves planning, physical flow, and collaboration.

Measuring Performance for Continuous Improvement

Ultimately, the strength of your foundation is measured by its performance. The goal is not just to move goods but to do so efficiently and reliably, which directly impacts your bottom line and customer loyalty. Key metrics provide a clear scorecard for your international supply chain management efforts.

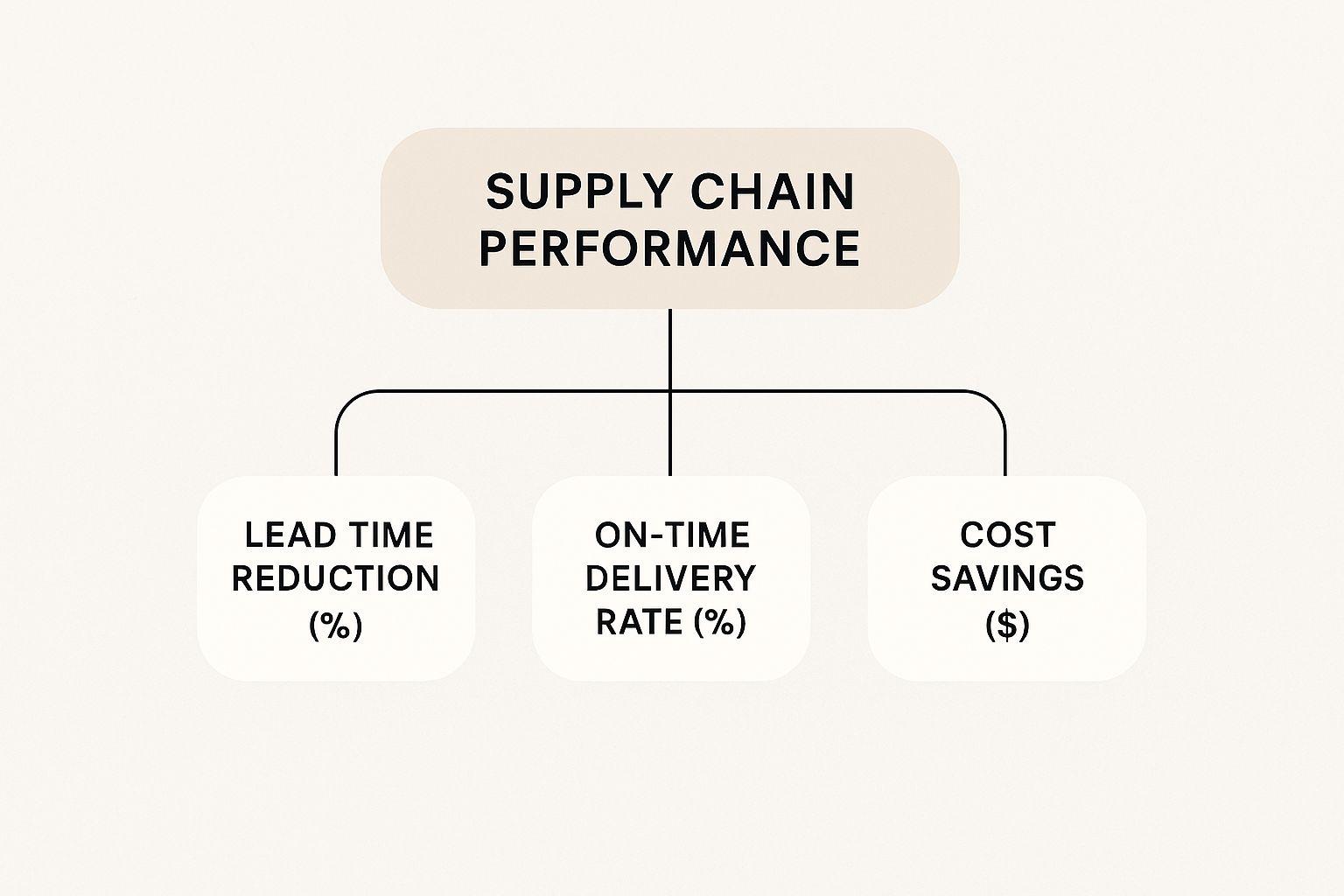

This infographic visualises the core outcomes of a high-performing supply chain.

As shown, a well-built foundation leads to tangible benefits like reduced lead times, higher on-time delivery rates, and significant cost savings. Each pillar—visibility, flexibility, and collaboration—contributes directly to these crucial outcomes, creating a competitive advantage that is difficult for others to replicate.

Navigating Global Regulations Without Losing Your Mind

International trade can feel like a complex maze. One wrong turn, and you hit a dead end; a right turn could lead your business to incredible new heights. For South African exporters, understanding the web of global regulations isn't just about ticking boxes—it's about learning the rules of the game to win. By shifting your perspective, compliance can change from a costly chore into a powerful competitive edge. This is a fundamental part of effective international supply chain management.

Decoding Customs and Documentation

Think of customs as a series of gateways, each guarded by a gatekeeper who needs a specific key to let you pass. Your documentation—the commercial invoice, certificate of origin, or bill of lading—is that key. A tiny mistake on a form can cause expensive delays, hefty fines, or even the seizure of your products. This is why getting your documentation right every single time is absolutely critical.

A great starting point for South African exporters is the South African Revenue Service (SARS); it's the authority managing all customs and excise duties. Their website offers essential resources and information to help you get started.

The SARS portal is your central hub for finding the correct tariff codes, submitting declarations, and staying informed about any changes in trade policy. Getting comfortable with this platform is the first step towards ensuring your goods clear customs without a hitch.

Before diving into specific requirements, it's helpful to see how they vary across major markets. The following table outlines the essential documentation and certifications needed for some key export destinations.

| Destination | Documentation Required | Certification Needed | Processing Time |

|---|---|---|---|

| European Union (EU) | Commercial Invoice, Bill of Lading/Air Waybill, Packing List, EUR.1 Movement Certificate | CE Marking (for many products), EORI Number, REACH (for chemicals) | 1-3 days |

| United States (US) | Commercial Invoice, Bill of Lading/Air Waybill, Packing List, Importer Security Filing (ISF) | FDA approval (for food/drugs), FCC certification (for electronics) | 2-5 days |

| United Kingdom (UK) | Commercial Invoice, Bill of Lading/Air Waybill, Customs Declaration (SAD) | UKCA Marking (replaces CE mark), EORI Number | 1-3 days |

| China | Commercial Invoice, Packing List, Bill of Lading, Certificate of Origin | China Compulsory Certification (CCC), AQSIQ registration | 3-7 days |

As you can see, each market has its own unique set of rules. For example, while the EU requires a EUR.1 Movement Certificate for preferential trade, the US demands an Importer Security Filing (ISF) for sea freight. Planning for these differences is key to avoiding surprises.

From Compliance Burden to Business Advantage

The smartest companies don't just follow the rules—they use them to get ahead. For example, understanding the African Growth and Opportunity Act (AGOA) can grant many South African products duty-free access to the massive US market. This can give you a major price advantage over competitors from other countries. Building a strong compliance framework means treating regulations not as hurdles, but as part of your strategic playbook.

This forward-thinking approach aligns with the South African government's efforts to improve transparency and efficiency in trade. The policy frameworks guiding international supply chain management are there to help businesses manage the complexities of global sourcing while supporting local economic growth. These standards also aim to minimise risks like fraud, which has been a challenge for supply chains in the region. You can find more specific examples in publications like the West Rand District Municipality’s quarterly report on supply chain management.

Turning Global Risks Into Manageable Challenges

Every international shipment is a calculated gamble. For South African exporters, the world of international supply chain management is dotted with unpredictable variables. One day it's currency fluctuations erasing your profits; the next, it's geopolitical tensions suddenly closing a critical shipping lane. The goal isn't to avoid risk entirely—that’s impossible—but to build a business that can absorb these shocks and adapt. Smart risk management is what turns potential disasters into manageable speed bumps on the road to global success.

Effective strategies start with proactively identifying what could go wrong. This means looking beyond obvious logistical delays to consider wider economic and political threats. A practical first step is building redundancy into your operations. Think of it like having a spare tyre for your car; you hope never to use it, but you're incredibly relieved it's there when you need it. This doesn't mean duplicating every single process, but it does mean finding critical single points of failure and developing alternatives.

Diversification and Contingency Planning

A common weak spot is relying too heavily on a single supplier or market. If all your key components come from one factory, or all your sales are concentrated in one country, your entire business is exposed to a single event. A “supplier +1” strategy, where you keep a relationship with a backup supplier, is a powerful way to counter this. It gives you the flexibility to pivot quickly if your main source is disrupted by anything from a local labour strike to a natural disaster.

In the same way, diversifying your customer base across different regions can shield your revenue from localised economic downturns. This kind of proactive planning is the core of a resilient supply chain. Visualising these potential disruptions helps to make them more concrete and easier to plan for.

This is where scenarios from global risk experts become extremely useful, as demonstrated in this example from Lloyd's.

The screenshot shows several high-impact scenarios, including cyber-attacks and geopolitical conflicts, which can create ripple effects across global trade. This type of forward-thinking analysis helps businesses shift from a reactive to a proactive risk stance, building contingency plans for events that might once have seemed unimaginable.

Financial and Insurance Buffers

Beyond operational tactics, financial instruments and insurance products provide another layer of security. For example, marine cargo insurance is essential, covering the loss or damage of your goods while they are in transit. For a South African business exporting high-value goods like wine or electronics, a single lost container could be devastating without proper cover.

Managing currency risk is also vital. The Rand's volatility can quickly turn a profitable export deal into a loss. Using financial tools like forward exchange contracts (FECs) allows you to lock in an exchange rate for a future transaction. This removes uncertainty and protects your profit margins. When combined with strong operational planning, these tools form the foundation of a secure international supply chain management system, turning global risks into challenges you are fully prepared to meet.

Leveraging Technology Without Breaking The Bank

The move from reactive firefighting to predictive intelligence has reshaped international supply chain management, a shift made possible by accessible technology. South African exporters no longer need enormous budgets to hold their own against global competitors. Instead, they can adopt smart, cost-effective tools to gain visibility and efficiency. From Internet of Things (IoT) sensors monitoring the temperature of perishable goods on long sea voyages to affordable cloud-based platforms, technology is levelling the playing field.

This digital adoption helps companies move away from guesswork and towards making decisions based on solid data. For smaller businesses, the secret is to focus on tools that deliver the biggest impact without demanding a complete operational overhaul.

Starting with Scalable Solutions

You don’t need to install a massive, enterprise-wide system from the get-go. Many South African businesses find success by starting with affordable technologies that offer a high impact:

- Cloud-Based Logistics Platforms: These software-as-a-service (SaaS) tools provide enterprise-level features for a monthly fee. This removes the need for a large initial investment in IT infrastructure. They act as a central hub for shipment tracking, documentation, and communication.

- GPS and IoT Sensors: Simple, low-cost trackers can be placed in containers to give you real-time location data. For delicate cargo like fresh produce or pharmaceuticals, IoT sensors can monitor conditions like temperature and humidity. This provides critical quality assurance and helps prevent costly spoilage.

- Automated Quoting and Booking: Tools that automate the process of getting freight quotes and booking shipments save a huge amount of administrative time. This frees up small teams to concentrate on more strategic work, like growing the business.

These entry-level technologies build a solid foundation of visibility. This screenshot from SAP shows how a modern supply chain platform brings together different functions into a single, easy-to-read dashboard.

The image illustrates how planning, manufacturing, and logistics are all connected, giving you a complete view that supports better decision-making. For a growing South African exporter, achieving this kind of oversight is the first step towards optimising the entire operation.

Calculating the Real Return on Investment

Bringing in new technology requires a clear business case. The return on investment (ROI) isn't just about direct cost savings; it's also about reducing risk and keeping customers happy. For example, spending R15,000 on IoT sensors might seem like a lot, but if it prevents the loss of a single R300,000 shipment of wine, the ROI is immediate and significant.

To help you weigh the options, the table below outlines the typical costs, returns, and timelines for key supply chain technologies.

| Technology | Initial Investment | Expected ROI | Implementation Time | Primary Benefits |

|---|---|---|---|---|

| GPS Tracking Devices | R1,500 - R5,000 per unit | 200%+ (via loss prevention) | 1-2 weeks | Real-time visibility, theft reduction, improved delivery estimates. |

| IoT Sensors | R5,000 - R20,000 (starter kit) | 500%+ (via spoilage prevention) | 2-4 weeks | Quality control, regulatory compliance, risk mitigation. |

| Cloud Logistics Platform | R2,000 - R10,000 per month | 150%+ (via efficiency gains) | 1-3 months | Centralised data, reduced admin, better partner collaboration. |

| Automation Software | R15,000 - R50,000 (one-time) | 100%+ (via time savings) | 4-6 weeks | Faster quoting, error reduction, frees up staff for strategic work. |

As the table shows, even modest investments can yield substantial returns, not just in money but also in operational stability.

Furthermore, think about the time saved. If a cloud platform cuts down administrative work by 10 hours per week, that's over 500 hours a year your team can redirect towards business growth. When you evaluate technology, look beyond the price and consider the total value it creates. A smart investment can make your international supply chain management more resilient and competitive on the global stage.

Building Partnerships That Actually Last

In the world of international supply chain management, your success often comes down to the quality of your human connections. While technology and logistics are vital, it's the relationships that endure across borders, time zones, and cultural differences. For South African exporters, this means creating a global network of trusted allies who are as invested in your success as you are. It's about moving beyond simple, transactional deals to build strategic alliances that fuel growth for everyone involved.

Identifying and Vetting Global Partners

The first step is figuring out the right kind of partner for your business. This isn't just about finding the cheapest freight forwarder. It's about finding a logistics expert who truly gets the unique challenges of exporting from Africa. Similarly, a distributor in a foreign market should be more than a simple order-taker; they should be your eyes and ears on the ground, able to guide you through the complexities of European or American retail.

When you're sizing up potential partners, think about these key factors:

- Regional Expertise: Do they have a proven track record in your target market? Do they have a deep understanding of its specific customs, regulations, and business culture?

- Reputation and References: Can they share case studies or connect you with other clients who have faced similar hurdles? A solid reputation is non-negotiable.

- Communication Style: How responsive and open are they? When a crisis hits, you need a partner who communicates clearly and proactively, not one who goes silent.

- Cultural Alignment: Do their values match yours? If you pride yourself on quality and customer service, you need a partner who feels the same way. A mismatch here can cause constant friction.

Structuring Agreements for Collaboration

Once you've identified a promising partner, the agreement you draft will set the stage for your entire relationship. A well-designed contract does more than just protect your interests; it encourages genuine teamwork. Successful long-term partnerships are often built on agreements that include shared goals and performance incentives. This changes the relationship from a cost centre into a value-generating alliance.

Think of it on a larger scale. Trade agreements between countries lay the groundwork for how international business is conducted. The World Trade Organization, for instance, provides a framework that shapes the very partnerships you can form.

This shows how global trade policies create the environment your business operates in. It's crucial to team up with partners who understand these rules. Ultimately, building these resilient relationships is the most durable competitive advantage a South African exporter can have.

Measuring What Actually Matters

There's an old business saying: "What gets measured gets managed." In the high-stakes world of international supply chain management, this is a fundamental truth. For South African exporters, choosing the right metrics is the difference between thriving on the global stage and just getting by. Simply tracking whether a package arrived isn't nearly enough. You need to decode the key performance indicators (KPIs) that reveal the true health of your operation and guide your strategy.

Forward-thinking companies look beyond basic delivery confirmations. They use balanced scorecards that weigh financial performance against customer happiness, operational efficiency, and even sustainability targets. This approach gives you a complete picture with actionable insights, not just a confusing pile of data.

Beyond Delivery Times: The KPIs That Drive Strategy

To get a real sense of your performance, you need a mix of metrics that tell a complete story. Focusing on a few powerful KPIs helps you spot chances for improvement long before your competitors even know there's an issue.

Key metrics for South African exporters include:

- Perfect Order Rate: Think of this as your supply chain's report card. It measures the percentage of orders delivered to the right place, with the right product, at the right time, in the right condition, and with all the correct paperwork. A high rate, typically above 90%, shows a highly reliable and efficient operation.

- Landed Cost: This is the true total cost of getting your product into your customer's hands. It includes the item's price plus all transport fees, insurance, customs duties, and taxes. Tracking this figure accurately is essential for understanding your actual profitability.

- Cash-to-Cash Cycle Time: This metric measures how quickly you turn your investment in inventory back into cash in the bank. A shorter cycle is like having a fast-turning engine for your business; your capital is actively working for you, not sitting idle in a warehouse or on a container ship.

Modern analytics tools can bring these complex metrics to life, making it much easier to spot trends and identify problems at a glance.

As the dashboard shows, consolidating data on inventory, shipping, and order status into one view helps managers quickly assess how things are going. Seeing how these numbers relate to each other helps you pinpoint exactly where friction exists in your international supply chain management processes.

From Data to Decisions

The real goal is to turn this performance data into a competitive edge. By comparing your KPIs against global benchmarks—while keeping the unique conditions of African markets in mind—you can build a solid framework for continuous improvement. For example, if you find your landed cost for a shipment to Europe is 15% higher than the industry average, you can start investigating. Is it the inland transport in South Africa? The customs broker? The final delivery partner? This data gives you a map to find cost-saving opportunities.

A huge part of controlling your landed costs and shortening your cash-to-cash cycle is managing international payments effectively. Hidden bank fees and unpredictable exchange rate markups can easily inflate your expenses. With a solution like Zaro, you can sidestep these issues by using the real exchange rate for your cross-border transactions. This gives you greater control and predictability over a major component of your costs. Learn how Zaro can give you a clearer view of your international finances.